Printing complex biological structures for medical applications

The research centers CIC nanoGUNE and POLYMAT and the 3D printing company Indart3D are collaborating to produce a tool that creates human tissue with the precision and complexity required for tissue and organ regeneration and make it available to medical and research personnel. The project, known as NANOPRINT BIO, is the outcome of a unique collaboration between research centers and companies, and is supported by the Basque Government's R&D grant program Hazitek 2023.

In a society in which people are living longer and longer lives, tissue engineering is seeking to develop solutions to repair or replace damaged or diseased tissue and organs using a personalized approach, and that way offer specific treatments tailored to the individual needs of each patient. One of the greatest promises of tissue engineering is the creation of functional tissue and organs from the patient's own cells, thus providing a solution for currently incurable diseases.

NANOPRINT BIO has the potential to move a step further in this direction, thanks to the combination of advanced bioprinting and nanofabrication technologies. “This platform will combine advanced technologies to achieve a high degree of precision in the production of complex biological structures that have mechanical and biological properties suitable for use in biomedical applications,” explained Javier Latasa, leader of the project at nanoGUNE.

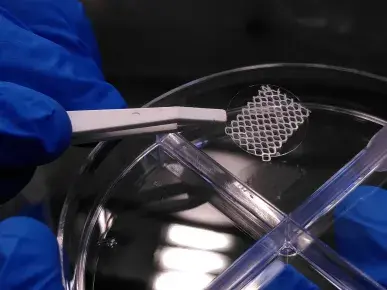

“The process basically consists of two phases and the same machine handles both: firstly, the scaffold is printed or obtained; this is the base which consists of a fibrous structure that provides robustness and at the same time offers the mechanical properties similar to those of the desired tissue. After that, a hydrogel is deposited on the base along with stem cells that will end up generating the desired tissue with an unparalleled level of structural precision, giving rise to a functional tissue,” added Javier Latasa.

He went on to say that “the project also envisages a final tool that is simple, so that it can be used directly by medical or research personnel. This will allow them to create tissue to perform personalized studies and evaluate how each patient will respond to specific drugs and therapies”.

The three organizations involved in the project agree that “this innovative tool has the potential to revolutionize the biofabrication of human tissue and improve the quality of life of many patients across the world, as it allows tissue characteristics to be reproduced more accurately”. In other words, “we are getting closer and closer to the exact reproduction of actual tissue,” concluded Javier Latasa.