Related news by tag Nanomaterials

CIC nanoGUNE is participating in two European projects to train young researchers

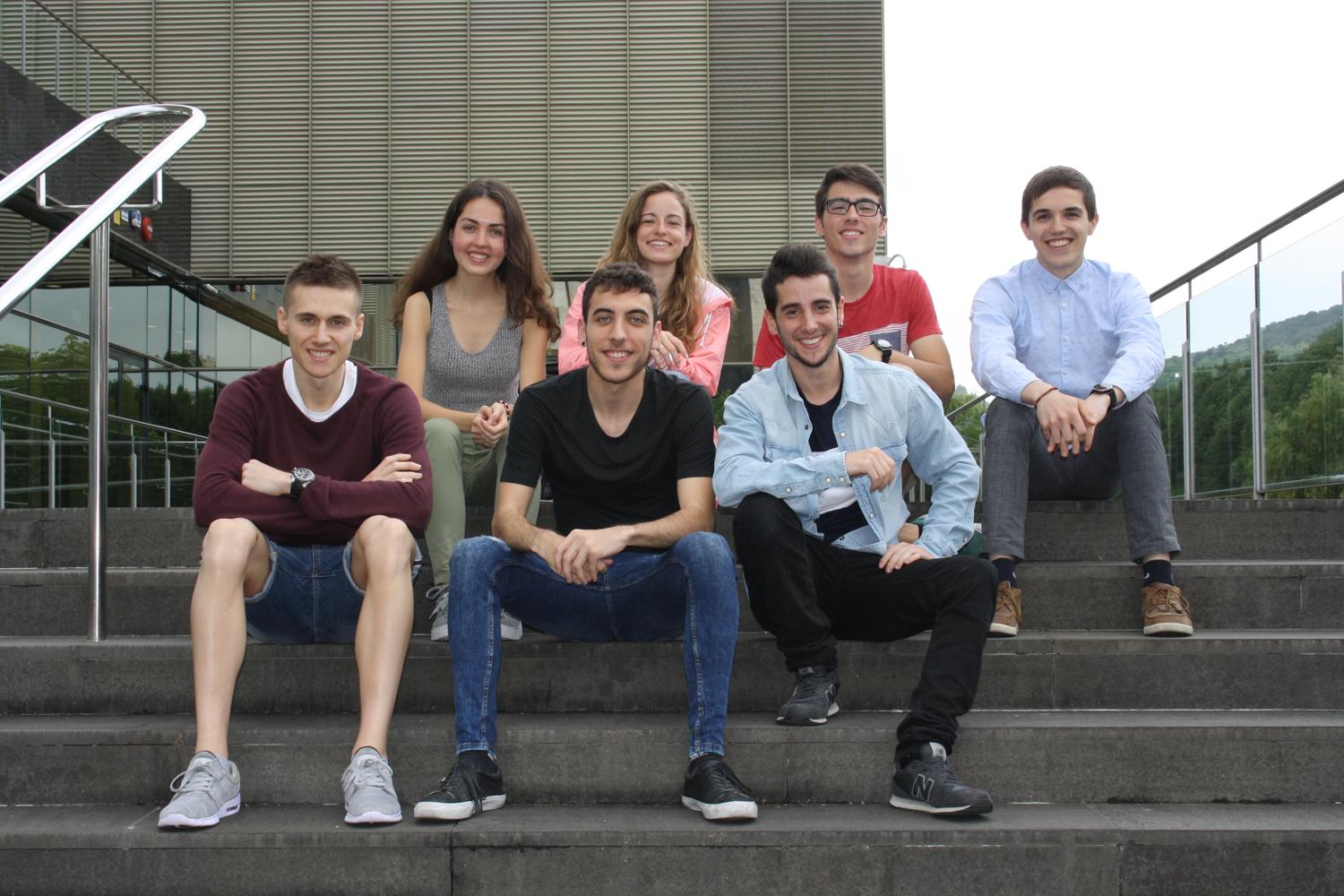

Students from UPV / EHU, Tecnun, UAB and the UB carry out summer internships at CIC nanoGUNE

On Tuesday, 19 June, we welcomed a group of internship students that will carry out a research project at NanoGUNE during the summer. The director of the center, Jose M. Pitarke, received the students with a presentation talk about nanoGUNE, that was also attended by the researchers that will conduct the students’ projects.

The 11 students come from different universities, among which are, Unibersity of the Basque Country (UPV /EHU), Tecnun, Univeristy of Barcelona (UB), Autonomous University of Barcelona (UAB). This program offers to the students a real experience of work in a research laboratory in order to make it easier for them to take decision about their future professional life.

The students will collaborate and learn with the different research groups at nanoGUNE, such as nanooptics, nanodevices or nanomagnetism. They will carry out a research project for two months following the instructions of a researcher of their group.

Some of them started the internships at the beginning of the month and they have been very involved in the group’s work. "The truth is that we started very suddenly; the very first day they took me to the laboratory," says Amaia Ochandorena, a student of Biochemistry and Molecular Biology at the UPV/EHU.

All the students knew CIC nanoGUNE and stressed that "it is an important research center" and "offers and works with topics of much interest".

For these students, and also for undergraduate students of general, nanoGUNE offers the possibility of collaborating with the center for the completion of final graduate or master thesis projects, for which also opens a call for grants every year.

The social challenge to reduce and prevent the presence of plastics in the seas up for debate

This one-and-a-half day European conference transversally and openly tackled the social challenge to reduce and prevent plastics and microplastics ending up in our oceans. Despite measuring less than 5 mm in all their three dimensions, microplastics include all those minute pieces of plastic that can be easily ingested by ocean inhabitants. More specifically, the three main aims being pursued were as follows: to understand the state of the ocean and the current consequences, to share possible solutions, and to work together to identify problems and barriers that exist with respect to turning the challenge into an achievable reality.

What was unique about the event was that besides gathering together within one and the same space people from across Europe, from Portugal to Greece including Germany and Slovenia, it brought together a group of very different people from the fields of science, technology and industry, as well as political players and the general public. These fields were represented, for example, by the European Commission’s Directorate General for Maritime Affairs and Fisheries (DG MARE), companies such as Nestlé España, Duni and SUEZ, university members (UPV/EHU-University of the Basque Country, University of Salerno (Italy), Leuphana University Lüneburg (Germany), etc.), European research centres and NGOs.

The first question tackled by the group of 17 participants was: What actions are needed to reduce and/or prevent the presence of plastics and microplastics in the ocean? Backed by European Union data on the production of single-use plastic products and “packaging”, the recycling of these materials, the export rate of “rubbish" to less developed countries or incineration, various plausible actions were put forward to encourage the reduction, re-use and recycling of plastic over the next 5 years. So the need to create easily accessible, transparent information was highlighted, and the importance of the circular economy that seeks to encourage the use of plastic debris as a raw material in producing new value plastic products was stressed. What is more, and along these lines, a proposal was made to set up an ecolabel that would inform the consumer in an accurate, straightforward and transparent way about the global impact of the product or packaging.

Events of this type are part of the European Commission’s strategy to transversally tackle the complex challenges facing today’s society so that solutions that are better aligned with the needs and expectations of society as a whole can be built. According to the event coordinators Nagore Ibarra González and Mato Knez of nanoGUNE, “such events help to guarantee more sustainable research and innovation on a human as well as environmental and economic level”. Organizers and participants rated the meeting highly positively, they “expressed great interest in continuing to collaborate in this direction as well as a clear commitment to address this challenge”.

Alternatives to plastic at nanoGUNE

By getting involved in social awareness about finding alternatives to plastic, nanoGUNE has internally committed itself towards a technology that could offer fully biodegradable packaging. As Ainara Garcia-Gallastegui, head of Technology Transfer at nanoGUNE, explained, “we have developed a technology that has the capacity to generate fibrillar structures using sugars or natural proteins, such as milk casein”. These threaded compounds could be produced in the form of films that could be used directly in food packaging and replace plastic packaging completely. Likewise, and given the need to replace single-use plastic packaging, sights are being set on cardboard-based packaging. “Our technology,” explained Garcia-Gallastegui, “may provide a totally biodegradable coating for the cardboard, thus offering the barrier properties needed between the food and the packaging surface”. So “the challenge is to produce completely plastics-free packaging while at the same time keeping its functionality intact”, she added.

The results of this dialogue and the sharing of it will be published shortly at: https://www.nanogune.eu/event/plastics-our-ocean-micro-or-macro-challenge

nanoGUNE launches a new summer internship call for university students

Through this programme the Basque nanoscience research centre will this summer be receiving about ten new students in their 3rd and 4th years of Physics, Chemistry, Biology and Engineering. For a period of six weeks or two months the young students will be collaborating with nanoGUNE researchers in their research projects on subjects such as electron/spin phenomena and magnetism, nanoscale optics, nanoscale materials and nanobioengineering, among others.

To participate in the summer internship programme any students who are interested will need to submit their applications online via the nanoGUNE website, the deadline being 16 February. Full information relating to the call is available via the nanoGUNE website (www.nanogune.eu)

CIC nanoGUNE and CIKAUTXO join forces to optimize rubber

CIC nanoGUNE expands its patent portfolio

The diversity of application fields demonstrates the great versatility of nanoscience research, and the increase in licensed methods and technologies demonstrates its ability to improve and add value to industrial processes and products. "Our goal is to continue doing research of excellence and transferring those specific developments with the potential to improve the competitiveness of companies to the economic sector," explained Ainara Garcia-Gallastegui, head of Technology Transfer at nanoGUNE.

Registration period for the summer internship program open

CIC nanoGUNE has just launched the program for summer internships, which runs every year. University students are offered the chance to get involved in the activity of a world-class research center.

CTECHnano, tailor-made solutions for the industry

“The aim is to provide solutions and consulting services for the development of processes and products to companies, and to offer also instrumentation or technical means so that they can do it in their own facilities” explains the Ikerbasque professor Mato Knez, leader of nanoGUNE´s Nanomaterials group and scientific advisor of CTECHnano.

CTECHnano is focused on customers looking for innovative products, working to overcome challenges in the field of thin-film coatings or trying to improve theperformance of their current processes. “We are thinking about sectors that seek innovation in order to open new markets. There are many industries that produce in the same way as they did twenty or fifty years ago”, tells Mato Knez. “Our idea is to help them to innovate by using the ALDtechnology. In this way they may adapt and improve the functionalities and properties of the materials, eventually obtaining new products” adds Knez. CTECHnano has a very strong experience in applying ALD technology to a variety of materials. “If a customer needs a tailored solution for a challenging development of materials, we will be offering a solution wherever possible. For this purpose, we have appropriate instrumentation for processing and characterization as well as the experience, as nanoGUNE´s Nanomaterials group is a reference in the use and development of this technology.

Why using ALD technology?

ALD technology allows changing the properties of materials. A very thin layer of only a few nanometers is deposited onto the substrate covering its entire surface. With such thin coatings many properties of the original material are retained, but at the same time, additional properties can be supplemented.

ALD provides a very controlled way to deposit thin films with thickness control on the atomic scale. Also, the growth of multilayer structures composed of different materials is straightforward. Due to the precision of the process and its reproducibility, it is already an established processing technology in the field of modern micro and nano electronics. ALD is typically run at temperatures lower than the competing vacuum based deposition processes, including chemical vapor deposition or thermal evaporation. The lower processing temperature additionally allows working with fragile substrates, such as biological or polymeric samples. This small, but important difference makes ALD the method of choice for many emerging applications such as, flexible electronics or composite materials design.

A strong team

Although being new, the company unites an experienced and complementary team working together. nanoGUNE has been the promoter of CTECHnano and two more companies —AVS and Cadinox— joined nanoGUNE for bringing CTECHnano to life. AVS and Cadinox have broad experience in design, manufacturing, integration, test and delivery of equipment to technology driven markets. “They are two ideal and strong partners for CTECHnano” says David Talavera, manager of the company. “The most important point is that all together we have the scientific and technological capability to beneficially adapt to customers´ needs”, he adds.

CTECHnano’s website is www.ctechnano.com

CIC nanoGUNE

The CIC nanoGUNE Nanoscience Cooperative Research Center, located in Donostia-San Sebastian (Basque Country), is a research center set up with the mission to perform word-class nanoscience and nanotechnology research for the competitive growth of the Basque Country.

AVS

AVS (Added Value Solutions) conceives and delivers scientific instrumentation in the fields of Astrophysics, Particle physics, Space and Neutron and X ray sources. AVS designs and develops high precision instrumentation working under harsh environments such us UHV, Radiation, High magnetic fields and cryogenic temperatures, covering design, manufacturing, integration, test and delivery under EN 9100 certification. AVS offers effective reliable and innovative solutions for technology driven markets. It is an open minded, flexible and creative organization ready to take new challenges and new ventures.

Cadinox

CADINOX, familiar company since 1966, dedicates to the mechanowelded fabrications of equipemnts for complex and unique installations. In its facilities located at Belauntza, 8600 covered s.m. with weight capacity up to 60 tons, 65 qualified people cover all the processes to offer an integral solution: cutting, forming, welding and associated NDT, surface treatment and final machining. It includes also the testing and mechanical assembly operations.

Technology developed at CIC nanoGUNE driving forward innovation in the textile industry

Innovation for the textile industry is not exclusively in design and fashion. The industry and the market are increasingly calling for innovative textiles that are adapted for the use for which they are designed. Over the last few decades, nanotechnology has developed various techniques to modify the properties of materials “à la carte”, which is why it is an indisputable ally in the development of new fibers that provide our garments with new properties, making them tougher, more waterproof, UV protective, antimicrobial, stain repellent, etc.

nanoGUNE Scholarship: call for Master Thesis students

The Scholarships will be of a total amount of 3,000€. This amount is for the whole period and will not be compatible with any other grant or funding awarded for the same purpose. Candidates have to be pre-registered and accepted at the above mentioned Master degrees in order to be eligible for these grants. Interested candidates can find all the information about the offered master projects and the application process following this link.

Besides the grants, nanoGUNE offers Master students coming from any official Master degree the possibility to develop their Master Thesis within one of its research groups.

Developing nanomaterials to conserve cultural heritage

Developing protective coatings for cultural heritage conservation and for the building industry poses a key challenge. These coatings not only have to be resistant and durable, but also compatible and tough in the face of adverse environmental factors such as humidity, thermal variation and atmospheric contamination.

Itxasne Azpitarte to receive top student award of the Master in New Materials

“I got the news last week and it was a great surprise in fact. When we get involved in our everyday work, we ‘forget’ all about the Master’s degrees, courses, etc. done the previous year,” said Azpitarte.

She will be receiving her diploma on 11 March as part of the Master’s Week 2016 when there will be an act of recognition and awarding of diplomas on the Bizkaia Campus for the best students on the Master’s courses during the 2014/2015 academic year.

This Master’s aims to provide students with a solid grounding in the latest methodologies relating to synthesis, characterisation, properties and applications in the field of new materials, and train them to make decisions in the scientific field, specifically in that of advanced materials, as well as to equip them to conduct research work in groups.

Summer Internship Program: call open until 5 February

NanoGUNE has just opened the registration period for the Summer Internship Program.

This year, we offer up to 13 projects for university students in the 3rd and 4th year of Physics, Chemistry, Biology, Engineering, and Mathematics. They will have the chance to get a closer look at the activity taking place at a cutting-edge research center for between six weeks and two months during the summer. This experience enables university students to collaborate with nanoGUNE researchers on their research projects in a whole range of fields, such as nanomagnetism, self-assembly, nanobiomechanics, nanodevices, nanomaterials, nanoimaging, and nanoengineering.

All the information about these projects, timetables, pay, etc. can be checked out at: https://www.nanogune.eu/summer-internship

Anyone interested in participated in the selection process needs to send an email attaching his/her academic record and CV to the address provided on the webpage no later than 5 February 2017. The students selected will be asked to attend an interview on 17 or 24 February.